In the ever-growing textile and fashion industry, embroidery machines play a pivotal role in producing high-quality designs at scale. For factory owners and production managers, selecting the right embroidery machine can significantly impact productivity, quality, and profitability. But with so many options available, which machine truly stands out for industrial use? This guide dives deep into everything you need to know.

Why Choosing the Right Embroidery Machine Matters

Investing in the right embroidery machine is not just about buying a tool — it’s about enhancing your factory’s efficiency and output. A high-quality industrial embroidery machine helps:

- Increase Production Speed — Multi-needle machines with automated features reduce production time.

- Maintain Design Precision — Ensures consistent output, even for complex designs.

- Reduce Downtime — Durable machines with easy maintenance improve overall workflow.

- Save Costs Long-Term — Energy-efficient and reliable machines reduce operational costs and repair frequency.

Factories often struggle when choosing a machine that balances speed, precision, and affordability. That’s why understanding the core features is essential.

Top Features to Look for in a Factory Embroidery Machine

When investing in an industrial embroidery machine, these features are non-negotiable:

- Number of Needles

Multi-needle machines (6, 9, 12, or more needles) allow for multiple thread colors simultaneously, minimizing manual changes and saving production time. - Embroidery Speed

Machines with higher stitches per minute (SPM) are ideal for large-scale production. Typically, factory-grade machines run between 800–1,200 SPM. - Hoop Size & Versatility

Larger hoops can handle bigger designs, while adjustable hoops provide flexibility for various product types like caps, jackets, and t-shirts. - Automation & Software Compatibility

Modern machines support USB or network connections for digital patterns, automated trimming, and error detection, boosting productivity. - Durability & Maintenance

Look for machines made from high-quality materials that can withstand long hours of operation without frequent breakdowns.

Popular Embroidery Machines for Factories in 2025

Based on industry reviews and user feedback, some machines stand out for factory settings:

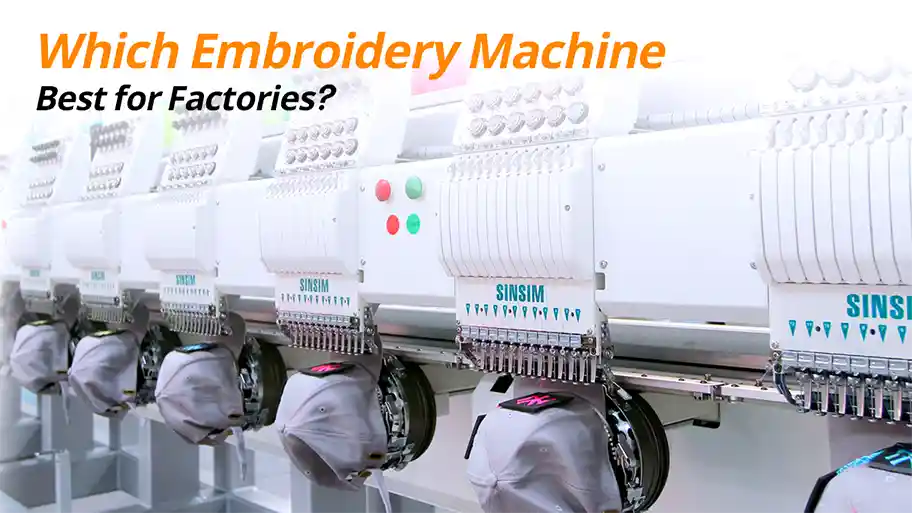

- Sinsim Industrial Multi-Needle Machines — Known for durability and consistent performance in high-volume factories.

Each brand has unique advantages, but factors like machine support, parts availability, and local service are equally important when making a factory investment.

Cost vs. Productivity: What You Should Know

While the initial investment for an industrial embroidery machine may be high, the returns justify the cost if chosen wisely. Key considerations:

- High-speed machines save labor and time.

- Multi-needle machines reduce thread changes and manual errors.

- Energy-efficient machines lower operational costs.

A well-chosen machine pays off quickly in productivity and reduced maintenance costs.

Real-World Testimonials

Many factories have upgraded their production lines with modern multi-needle machines, reporting:

- 50–70% faster production rates compared to single-needle or older machines.

- Consistent quality with fewer rejected products due to errors.

- Long-term reliability, reducing downtime and repair costs.

Final Recommendations

For factories aiming to scale their embroidery operations, investing in a durable, multi-needle, high-speed machine is crucial. Sinsim and Tajima remain popular choices globally, while local support and service options can make or break your experience. Always consider your factory’s production volume, product types, and budget before making a purchase.